The salinity of this type of water is 2000 mg/L – 10000 mg/L. In its treatment, pressures of 14 bar – 21 bar are used to achieve rejection coefficients greater than 90% and to obtain water with saline concentrations of lower than 500 mg/L, which are the values recommended by the WHO as a requirement of potability.

Treatment plants use membrane modules rolled in spirals. It is estimated that the costs for this type of plant are in the region of 0.25 $US/L of treated water/day, with the operating costs being equivalent.

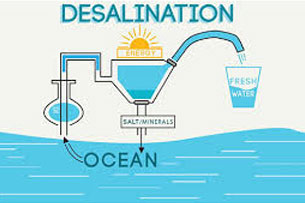

Depending on the geographical area, the salinity of this type of water is 30000 mg/L – 40000 mg/L. To meet the potability requirements, polyamide hollow fiber membranes are used which allow rejection coefficients to be achieved of greater than 99.3% with working pressures of 50 bar – 70 bar.

RO allows water of the quality demanded by the government residential colonies to be obtained from drinking water (concentration of dissolved solids < 200 mg/L). In MACONS RO system, for microbiological treatment we having in build UV Lamp Radiation and Ozone inject system online.

In the case of industrial wastewater, RO is used in those industries where it is possible to improve the efficiency of the process by re-operating valuable components that can be recycled in the production process: galvanoplasty industries and paint for metal structures, or where reuse of the treated water represents an important reduction in the consumption of water, e.g. textile industry.